- Home

- Products

- Carton/Tray Wrapper & Wraparound Case Packer

- Carton/Tray Wrapper Case Packer

- FYT-501&FM-7540-4L High-Speed Tray Shrink Wrapping Machine

Products

Products

FY-ROB Robotic System

Beverage & Food & Pharma Packaging Machine

High Speed Series Overlapping

Counting, Grouping

Flow Wrapper Packaging

L-Type Packaging

Carton/Tray Wrapper & Wraparound Case Packer

Carton/Tray Wrapper Case Packer

Tapes Packaging Solution

Automatic Shrink Sleeve Labeling Machine

Products

Bottom overlap shrink film packaging, suitable for production lines running at 400–600 BPM.

Features

- FYT-501 series are our newly developed models that meet the newest over-lap packaging systems adopted by the industries in the world. High speed, Nice packing, Functional, Simple maintenance, easy operation and manpower saving.

- Packing material is LDPE shrink film. Both transparent and printed shrink film can be used.

- Single film packing is overlapped at the bottom of the products, there are no heat seals on the packages.

- Multi-Axis of PC base programming control by color touch screen operation. Within specified range (L x W x H) for different products is completely simple for size-change on the screen.

- Each action and workstation of machines can be displayed on the screen for view.

- Film is delivered by Servo motor, so the film length is easily controlled. Sucking conveyor is equipped.

- Two film cradles at single-spindle air pressure can be exchanged. Each set can bear 60~90kgs of film roll.

- Film-rolling mechanism is controlled by Servo motor. the packing in different heights can proceed at any time. Automatic trip device for breakdown and lip type conveyor are also equipped.

- The machine can match the interlocking control system of before/after production lines.

- The machine body is made of standard steel #SS41 with powder painted surface. Inner oven is made of SUS#304.

- Electric heating stainless steel tube is equipped with fin and installed with ceramic adapter wires at two ends, so temperature can be adjusted. ABM Mineral Wood board covers heat-reserving layer.

- Twin circulation fans are to ensure even heat distribution inside shrink oven. Heat wind direction is adjustable.

- The machine's structure is melted and formed with square SS41 steel pipes with powder painted surface.

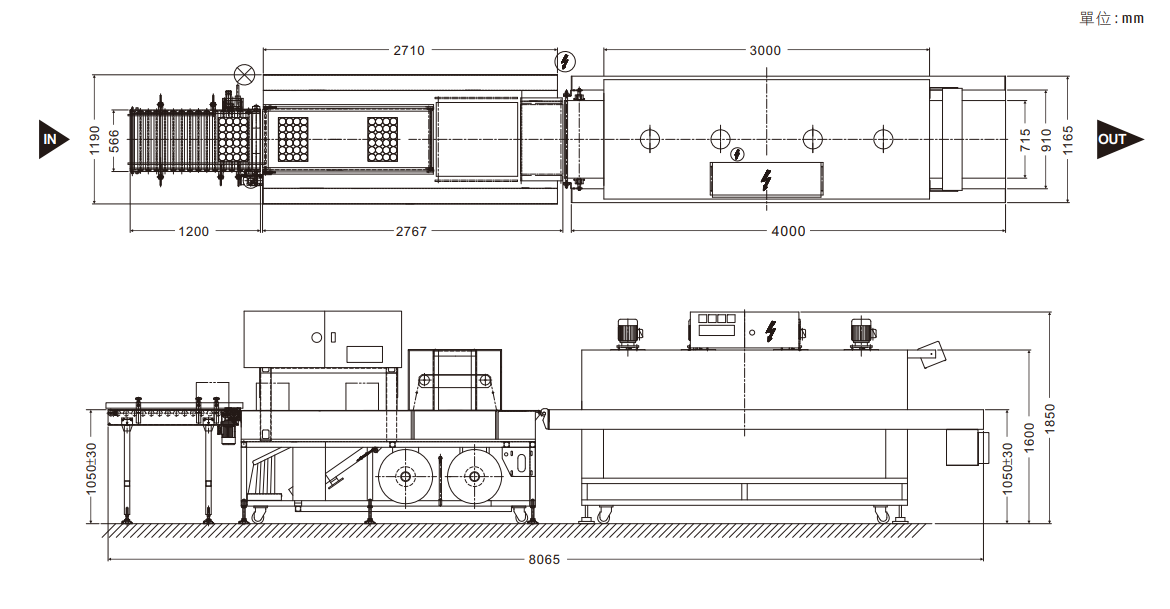

Machine Dimensions

Machine Specs

◎ Packaging speed depends on product size, packaging style, and the stability of the product on the conveyor.

◎ Machine dimensions are for reference only; please refer to the actual design.